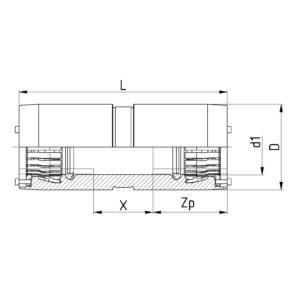

REINOGRIP Multi repair couplers, longitudinally force-locking

Repair coupling made of PE-HD with grip for various plastic pipes

Reinert-Ritz has the right solution for the restrained connection and repair of different plastic pipe materials with the multi-repair coupling.

With the patented REINOGRIP system, pressure pipes made of PVC, PP, PE100 and PE100-RC can also be connected to each other with a longitudinal force fit.

The multiple gripping elements only engage after manual release.

This enables the coupling to be fitted to the pipes quickly and precisely.

An EPDM lip seal provides a secure seal.

Tender text

PE100 fittings with tensile plug-in connection REINOGRIP system Generalpreliminary remarks The fittings to be offered must be made of material in accordance with the PE100+ Association and comply with DIN EN 12201 in terms of dimensions, tolerances and quality requirements. Proof of production on the basis of a quality assurance system in accordance with DIN EN ISO 9001 must be provided. A certificate in accordance with DIN EN 10204 must be provided by the manufacturer for all molded parts. Alternatively, the body of the molded part must be manufactured from a single piece of homogeneous semi-finished material using the injection molding process, even for more complex structures, in order to ensure the required reinforcement and thus high stability of the molded part. Semi-finished products made from winding rod or other subsequently applied reinforcements are not permitted. The tension-resistant plug connections must have grip elements, each with at least 5 grip teeth made of high-strength plastic, which are arranged on spring-loaded holders.

An elastomer ring must ensure that the grip is self-activating.

An elastomer profile ring must be fitted at the inlet of the plug connection as a wiper to prevent the ingress of dirt.

A pressure-tight System 3S lip seal in drinking water quality must be installed as a media seal.

Spigot ends on the fittings must be long in order to be able to carry out both plugging and HE butt welding or HW welding.

Flange connection dimensions must be designed in accordance with DIN EN 1092–1.

Depending on the type of mating flange, flange connections must be designed either as a loose flange connection or as a fixed flange connection (with the same nominal width). The backing flanges must be made of corrosion-free, fiber-reinforced plastic. The collar and flange must interlock positively at their connecting surfaces and the flange must also support the collar from the outside to counteract deformation.

This ensures that the flange connection can withstand full pressure in accordance with the pipe dimensions.

The backing flange is captively connected to the welding neck.

The use of a profile seal for flat-sealing collars is recommended if no other seal is available in the system.

Hydrant connection flanges must have an outwardly reinforced weld seam area designed for the load of the hydrant; DN 80 -> 110 mm outside diameter and DN 100 -> 135 mm outside diameter. The backing flange is made of corrosion-free, fiber-reinforced plastic, supports the PE collar from the outside and has a disc spring function that maintains the preload after tightening the screws.

Optionally available versions: Flange with O‑ring seal, socket for smooth spigot or bayonet spigot (sockets for hydrants) at the outlet of the hydrant fittings, version for PVC‑U, PP‑R or PP‑H pipes.

Read more

Standards/guidelines

DIN EN 12201, DIN EN 1092–1, DVS 2207, DVS 2210, DIN EN 10204, DIN EN ISO 9001, DIN EN ISO 50001, DVGW W 400–2, DVGW GW 335Permits/certificates

DVGW: DW-8616CP0454, DV-8606BT0423, DV-8611BT0424Acceptance test certificate 3.1 according to DIN EN ISO 10204 for the semi-finished material from the processed raw material with indication of MFR and OIT; only PE100 material in compliance with PE100+ Association

Manufacturer certified according to ISO 9001:2015 and ISO 50001:2011

Manufacturer:

Reinert-Ritz GmbH or equivalentPerformance specification:

- PE100 double coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD [d1] …

SDR …

Operating pressure … bar

- PE100 bend 1 x d, with push-fit coupling on both sides, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD [d1] …

SDR …

… degrees

Operating pressure … bar

- PE100 bend 1 x d, with push-fit coupler on one side, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD [d1] …

SDR …

… degrees

Operating pressure … bar

- PE100 tee, with all-round push-fit coupling, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD1 [d1] …

DN/OD2 [d2] …

SDR …

Operating pressure … bar

- PE100 tee with HP flange outlet, with push-fit couplers in the run pipe, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD [d1] …

SDR …

DN …

PN … drilled

Operating pressure … bar

- PE100 concentric reducer, with push-fit coupling on both sides, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for PE100 pipe of the size

DN/OD1 [d1] …

DN/OD2 [d2] …

SDR …

Operating pressure … bar

- PE100 concentric reducer, with coupler on one side, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, second side long for HW welding , for PE100 pipe of the size

DN/OD1 [d1] …

DN/OD2 [d2] …

SDR …

Operating pressure … bar

Read more

- PE100 repair coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and bolt preload for secure fixing, for pipes of the size

Material 1: □ PE100 □ PVC □ PP

DN/OD1 [d1] …

SDR …

Material 2: □ PE100 □ PVC □ PP

DN/OD1 [d1] …

SDR …

Operating pressure … bar

- PE100 push-fit socket, consisting of push-fit coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, and HP flange for PE100 pipe of the size

DN/OD1 [d1] …

SDR …

DN …

PN …

Operating pressure … bar

- PE100 telescope repair set, with push-fit coupling on both sides, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, for pipes of the size

Material 1: □ PE100 □ PVC □ PP

DN/OD1 [d1] …

SDR …

Material 2: □ PE100 □ PVC □ PP

DN/OD1 [d1] …

SDR …

Operating pressure … bar

- PE100 duckfoot bend for connection to hydrant, reinforced design, with push-fit coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with adapter for hydrants with bayonet spigot, for pipes of the size

DN/OD1 [d1] …

SDR …

Operating pressure … bar

- PE100 hydrant end piece for service line connection, reinforced design, with push-fit coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with adapter for hydrants with bayonet spigot, for pipes of the size

DN/OD1 [d1] …

SDR …

DN/OD3 [d3] …

SDR …

Operating pressure … bar

- PE100 tee for connection to hydrant, reinforced design, with push-fit coupler on both sides, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with adapter for hydrants with bayonet spigot, for pipes of the size

DN/OD1 [d1] …

SDR …

Operating pressure … bar

- PE100 cross for connection to hydrant, reinforced design, with all-round push-fit coupling„ pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with adapter for hydrants with bayonet spigot, for pipes of the size

DN/OD1 [d1] …

SDR …

Operating pressure … bar

Read more

- PE100 X‑cross for connection to hydrant, reinforced design, with all-round push-fit coupling„ pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with adapter for hydrants with bayonet spigot, for pipes of the size

DN/OD1 [d1] …

SDR …

Operating pressure … bar

- PE100 duckfoot bend for connection to hydrant, reinforced design, with push-fit coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with special flange connection (VP flange) of the same nominal diameter with fibre-reinforced backing flange at outlet, drilled according to DIN EN 1092–1, with spring effect for continuous bolt preload, for pipes of the size

DN/OD1 [d1] …

SDR …

DN …

Operating pressure … bar

- PE100 hydrant end piece for service line connection, reinforced design,with push-fit coupler, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with special flange connection (VP flange) of the same nominal diameter with a fibre-reinforced backing flange at the outlet, drilled according to DIN EN 1092–1, with spring effect for continuous bolt preload, for pipes of the sizes

DN/OD1 [d1] …

SDR …

DN …

DN/OD3 [d3] …

SDR …

Operating pressure … bar

- PE100 tee for connection to hydrant, reinforced design, with push-fit coupler on both sides, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with special flange connection (VP flange) of the same nominal diameter with fibre-reinforced backing flange at outlet, drilled according to DIN EN 1092–1, with spring effect for continuous bolt preload, for pipes of the sizes

DN/OD1 [d1] …

SDR …

DN …

Operating pressure … bar

- PE100 cross for connection to hydrant, reinforced design, with all-round push-fit coupling, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with special flange connection (VP flange) of the same nominal diameter with fibre-reinforced backing flange at outlet, drilled according to DIN EN 1092–1, with spring effect for continuous bolt preload, for pipes of the sizes

DN/OD1 [d1] …

SDR …

DN …

Operating pressure … bar

- PE100 X‑cross for connection to hydrant, reinforced design, with all-round push-fit coupling, pull-resistant according to DVGW, pressure class-compatible, with EPDM lip seal and dirt-repellent profile ring, with special flange connection (VP flange) of the same nominal diameter with fibre-reinforced backing flange at outlet, drilled according to DIN EN 1092–1, with spring effect for continuous bolt preload, for pipes of the sizes

DN/OD1 [d1] …

SDR …

DN …

Operating pressure … bar

Proof of delivery:

Reinert-Ritz GmbH

Ernst-Heinkel-Straße 2

48531 Nordhorn

Tel.: +49 5921 8347–0

Fax: +49 5921 8347–25

www.reinert-ritz.de

Email: contact@reinert-ritz.com