Maintenance and cleaning of sewage pressure pipes

Especially when working in manholes, accidents at work occur time and again, be it due to slipping from ladders or bumping into each other in the confined working space. A great danger when working in manholes is also the presence of sewer gases and/or gases escaping from the ground. NOnce these gases have been detected, the manhole must be ventilated using appropriate means and measures, and the resulting waiting time delays the start of the planned work. In addition, since the space required to accommodate and operate fittings in manholes must be taken into account for new construction as well as retrofitting, this can be associated with high costs.

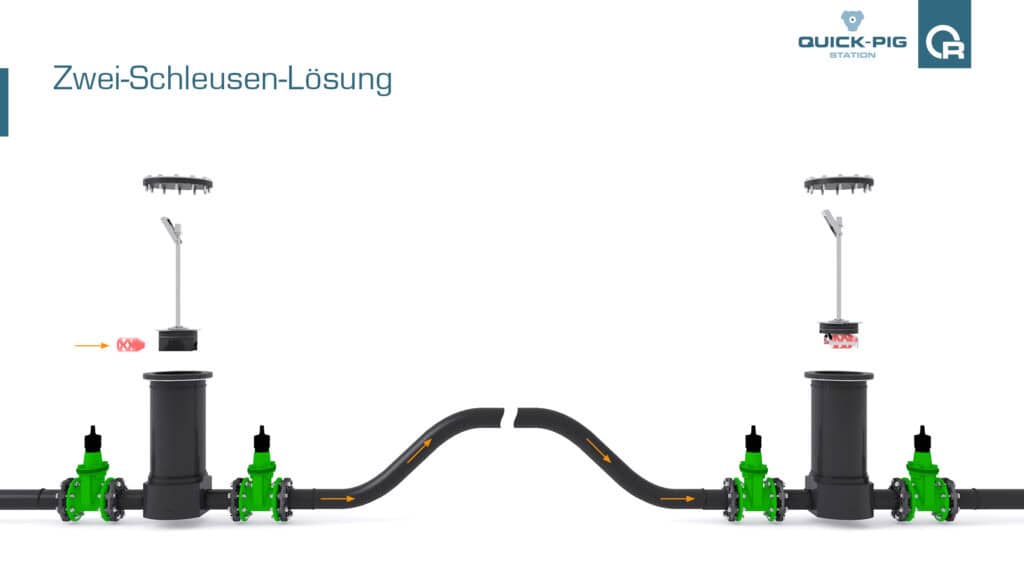

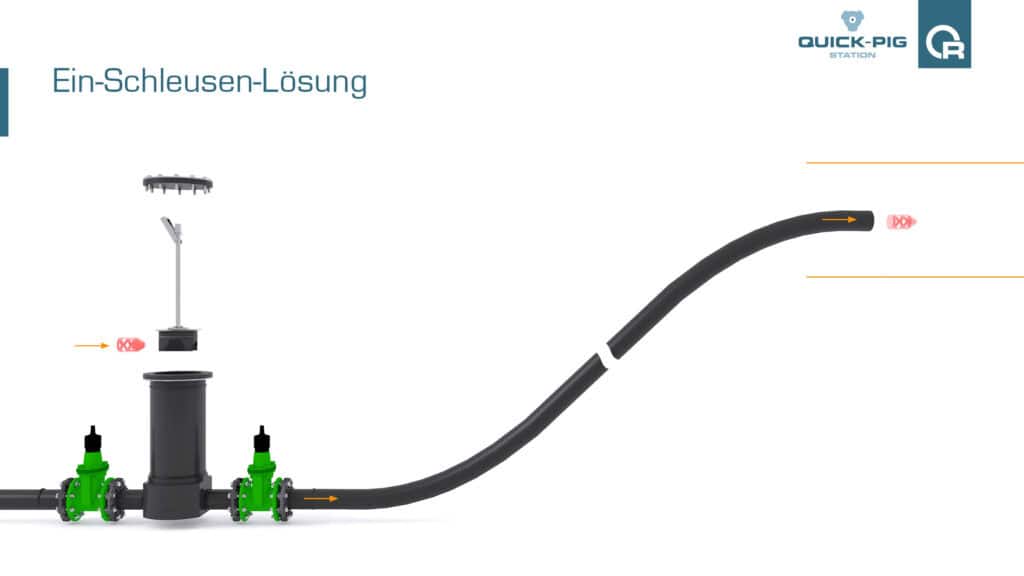

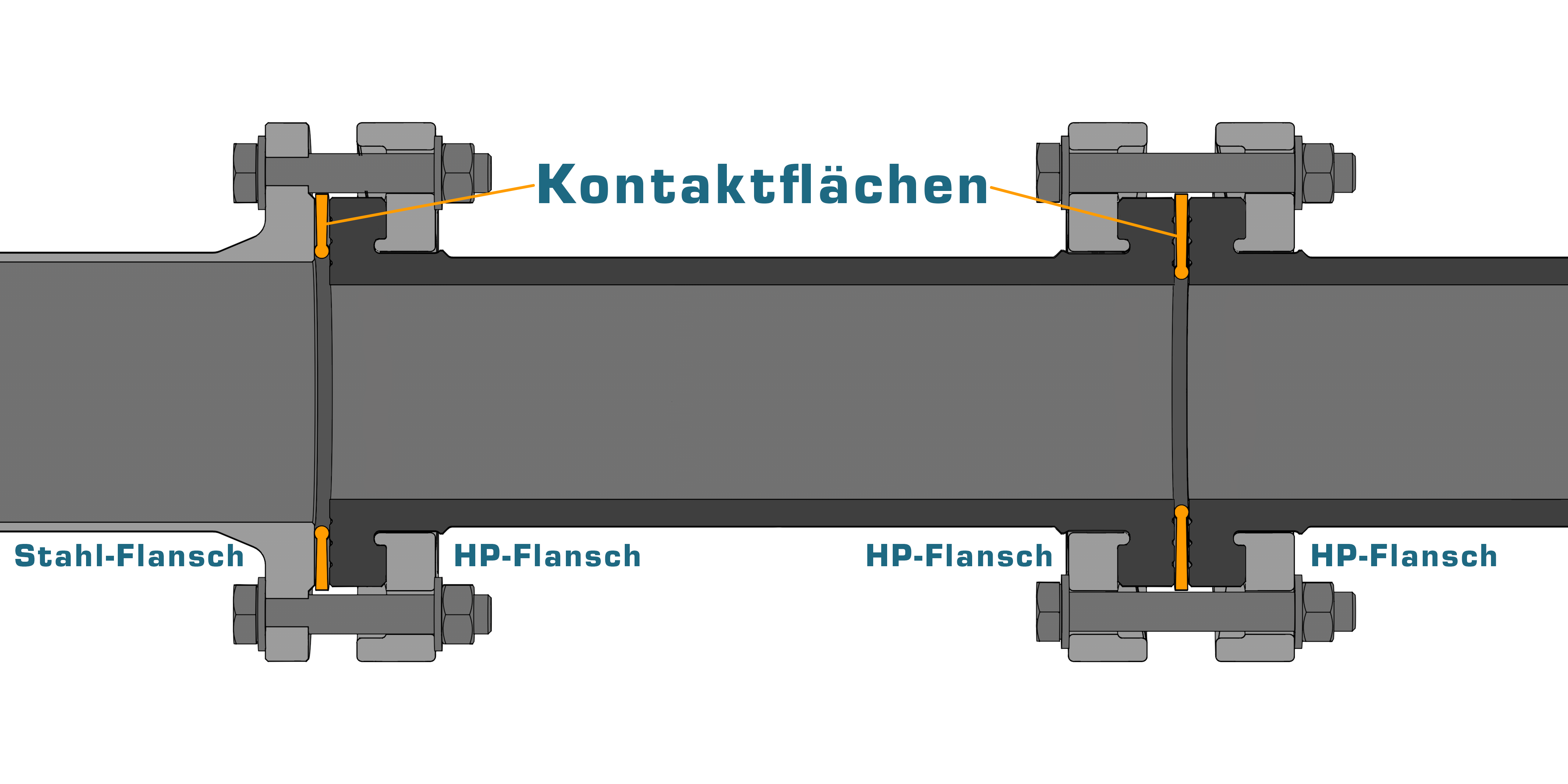

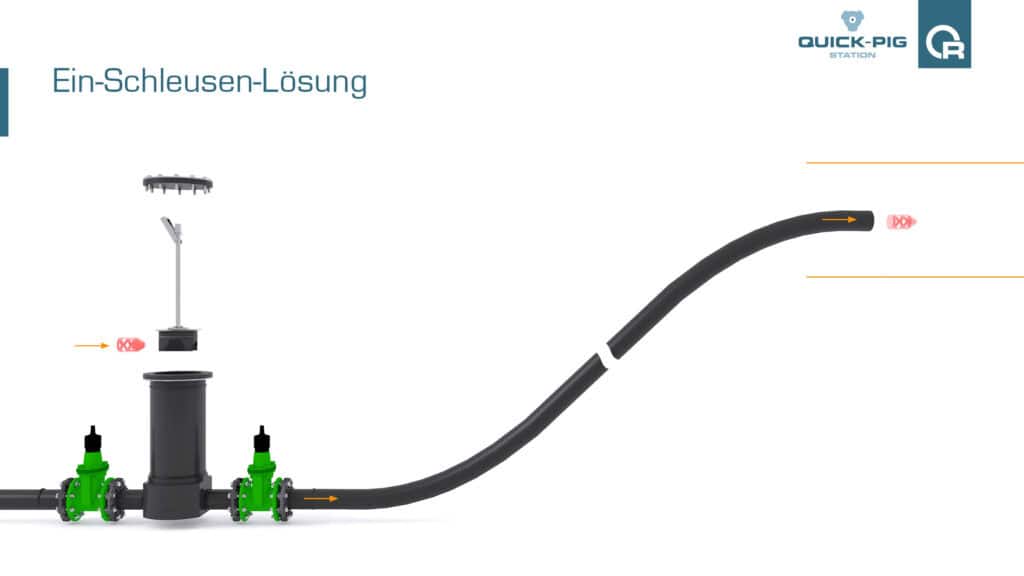

Therefore, Reinert-Ritz GmbH set to work, implemented the requirements specified by Hamburg’s municipal drainage system in a way that was suitable for plastic and tested them in the company’s own test centre. The result was a compact pigging station as an alternative to large, expensive concrete manholes, which can be installed under standard road covers next to existing pipes and cables. It eliminates the need to test for gas and pump out water, which can occur in manholes. The operation of the airlock is simple and fast thanks to the bayonet lock. According to the manufacturer, in addition to the construction costs, the life cycle costs due to maintenance operation are also significantly lower than the costs of the standard manhole solution. In addition, the pigging station facilitates the recording of the condition of the pressure pipe required by the various self-inspection ordinances of the federal states.

The first pigging station was installed in August 2014 in the Hamburg district of Lurup in an existing PE100 wastewater pressure pipe of dimension d 160 mm with little construction effort. After the successful successfully commissioned, pigging can now be carried out quickly and safely. And because the term “Molch” is “pig” in English, the name of the fast pigging station was also found: Quick-Pig.

The Zweckverband Lollar-Staufenberg (ZLS), which is active as a service provider in the areas of water supply, wastewater discharge and wastewater treatment, also used the Quick-Pig system for the first time in Hesse as part of a pilot project. The ZLS operates a total of seven sewage pressure pipes with a total length of about 5 km in its association area. They represent about 4% of the total network length of the ZLS. In the past, the operation and maintenance of the pressure pipeline systems, some of which are over 20 years old, focused primarily on the maintenance of the mechanical and electrical equipment of the pumping stations and pumping stations. In 2016, the rehabilitation of three older pumping stations was planned. For the cleaning of the pipelines, pig accesses were planned. The retrofitting of a pigging station was also planned for an existing sewage pressure line.

Since the cleaning and inspection of sewage pressure pipes was not possible with the usual method of gravity sewers, but at the same time the operational risk in the event of damage was much greater, the Quick-Pig system from Reinert Ritz GmbH was used.

In the meantime, more than 60 Quick-Pig pigging stations have been installed in Germany for pipe dimensions from d 63 mm to d 180 mm.

have been installed. Four Quick-Pig pigging stations of the dimension d 315 mm were even delivered to Scandinavia.

Could Quick-Pig spark your interest? Then you can find more helpful information here:

Product presentations and professional advice for your planning are available from our Sales team to Quick-Pig — contact directly!

Sales team to Quick-Pig — contact directly!